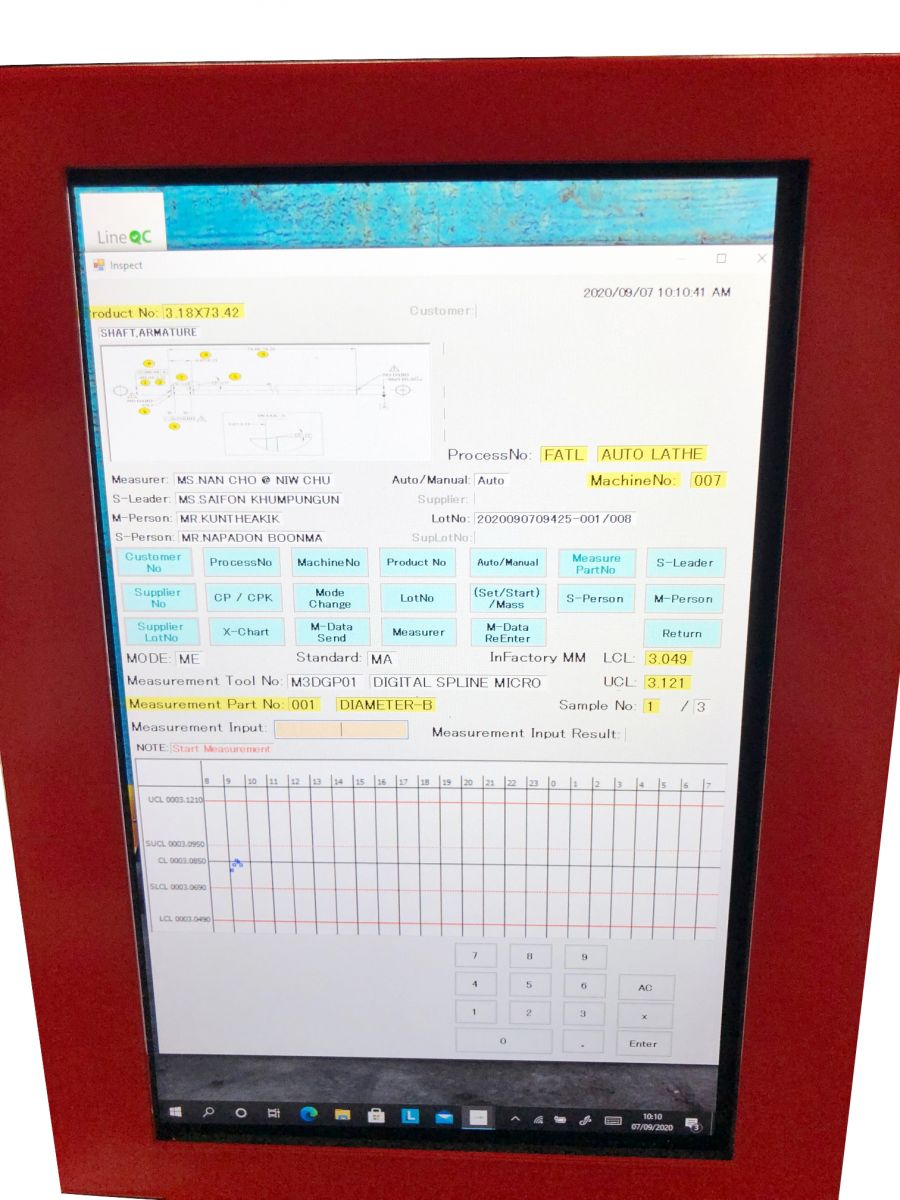

Manufacturing management / warning system

LINE QC SPECIALIST

Newly developed system to prevent NG (No good) products from being

produced during the manufacturing process! Eliminate in-process defects

How to stop the output of one defective product per million without automatic 100%

inspection? The answer is " Elimination of in-process defects"!

This is a revolutionary Nano Seimitsu system that allows the software to monitor the rules

determined by the manufacturing department and give appropriate instructions to the line

QC staff who handle the measuring instrument.

inspection? The answer is " Elimination of in-process defects"!

This is a revolutionary Nano Seimitsu system that allows the software to monitor the rules

determined by the manufacturing department and give appropriate instructions to the line

QC staff who handle the measuring instrument.

■ 3 features of LINE QC SPECIALIST

① Cannot make abnormal products

② Cannot operate or do work out of the rules

③ If an abnormal product is about to be created, the monitoring software will prompt the

machine to stop.

■ System details

・ Measurement instrument calibration management (calibration content, time)

= Software intervention in measuring instrument reliability

・ Divide between adjustment and start of mass production

= Systemize mass production approval

・ Divide between central control value setting during adjustment and control value

setting during mass production = Focus on central control during adjustment

・ Convey the measurement location and measurement frequency to the operators and

encourage them to measure the correct location with the correct control value.

・ If "measurement frequency cannot be observed", "measurement value has reached

the control value", or "instrument calibration time has been exceeded", the software

issues a warning

① Cannot make abnormal products

② Cannot operate or do work out of the rules

③ If an abnormal product is about to be created, the monitoring software will prompt the

machine to stop.

■ System details

・ Measurement instrument calibration management (calibration content, time)

= Software intervention in measuring instrument reliability

・ Divide between adjustment and start of mass production

= Systemize mass production approval

・ Divide between central control value setting during adjustment and control value

setting during mass production = Focus on central control during adjustment

・ Convey the measurement location and measurement frequency to the operators and

encourage them to measure the correct location with the correct control value.

・ If "measurement frequency cannot be observed", "measurement value has reached

the control value", or "instrument calibration time has been exceeded", the software

issues a warning