Date:

August 25, 20

Zero ppm will be the quality control standard in Thailand! - Total number inspection that does not put out non-conformity products of one per million -

30/04/2020

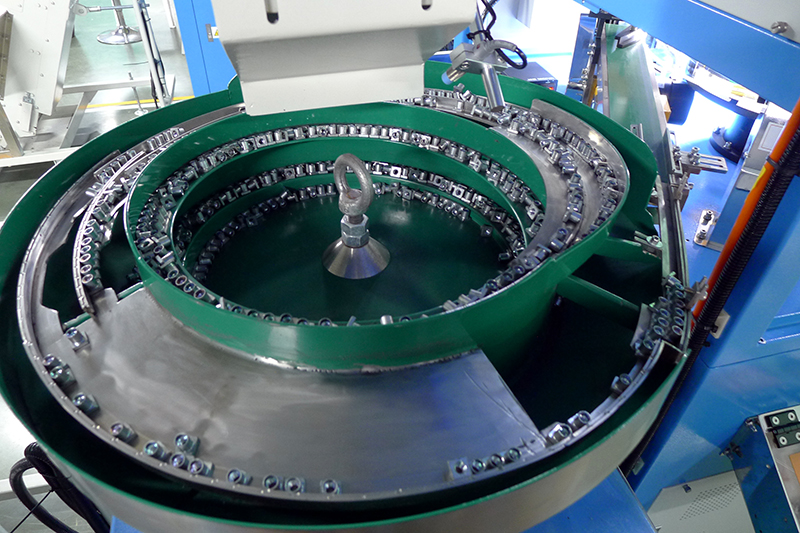

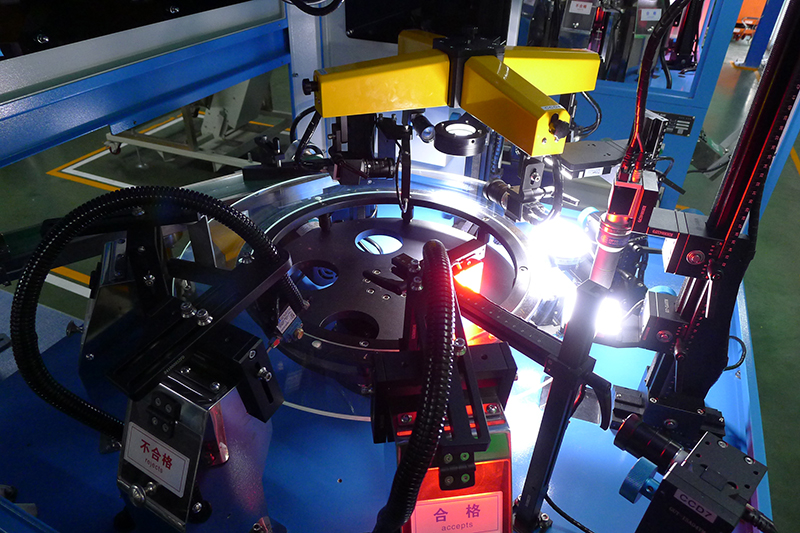

Inspect for non-conformity or not, parts that are not known from appearance. Prevent problems such as customer claims a recall after delivery to customers. ■ DECSYS Appearance semi-automatic inspection machine

A device that automatically inspects fine abrasions and dents. Unlike the human eye, it makes a judgment on a certain standard. Capture scan data from up to eight lines of different light conditions to detect defects such as scratches, dents, and dirt at a minimum 0.2 mm square level.

A company that works with automated machine manufacturers to propose a dedicated machine that can fulfill all the needs of its customers. The big attraction is the proposal power and the price competitiveness in which their know-how is packed.

■ LINE QC SPECIALIST Manufacturing Management System

A newly developed system to prevent issuing non-conformity parts in the manufacturing process! The software monitors the rules set by the manufacturing department and gives appropriate instructions to QC staff on the line handling the measuring instruments.

Customers are demanding a system to guarantees products fully free from non-conformity. However, there are few companies in Thailand and Japan that can meet this requirement. The automatic sorting and inspection system that NANO SEIMITSU proposes is to realize Zero ppm and brings higher grade quality improvement to the manufacturing industry.