Date:

September 02, 20

Provide high quality and accurate quantity counts! Nano Seimitsu started contracting the business of total inspection.

.jpg)

25/12/2018

”Now it is a worldwide movement to require high quality and accuracy even for only one automobile part. Therefore it is necessary to conduct a total inspection of finished products.” Said Mr. Nobuhiro Oishi, Managing Director of “Nano Seimitsu” selling inspection equipment and similar goods is located in Samutprakarn province near Bangkok. So far they have been selling automatic sorting equipment and similar goods to mainly parts manufactures. But they felt strongly that the market is changing in recent years, so they decided to set up a “sorting house” which they have had been planning for a long time. I have heard that they started contracting the inspection business seriously for small companies who have difficulty introducing equipment by themselves. After hearing this, the Samurai editorial department went to interview the company.

Preparing many sorting machines in the contracting business of total inspection that we have started

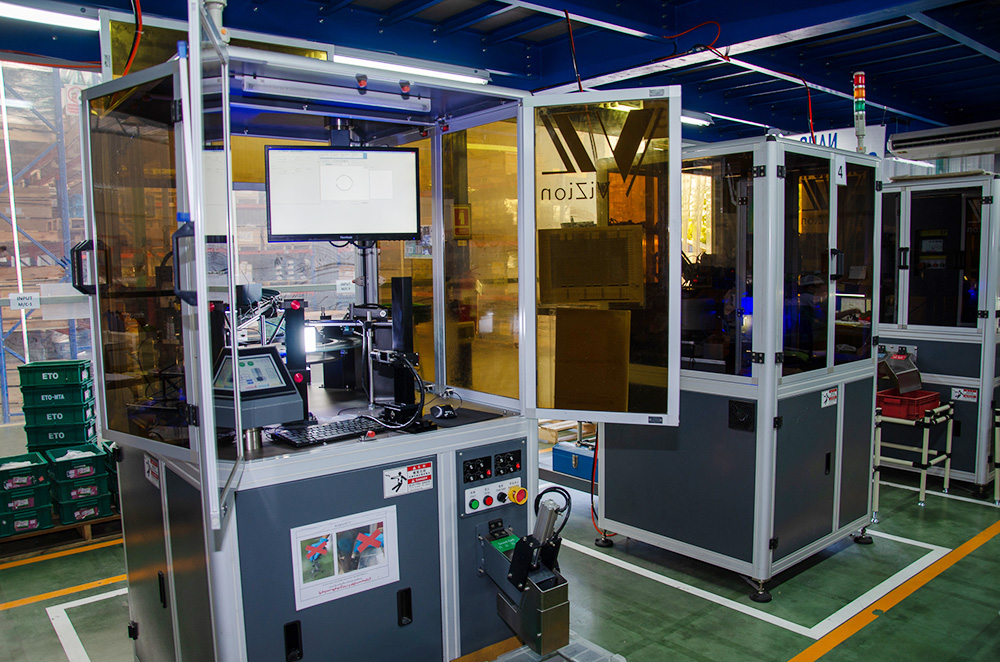

The sorting house was set up at a corner inside the company area. A total of 10 or more“VIZION” high-speed automatic sorting machines, appearance inspection machines“DECSYS”, tissue inspection machines, etc. were set up and the demo machine is always displayed and operating. The staff are also working hard beside the equipment to do any inspection that they just undertook. “It is a workshop, but we tried to make it similar to an exhibition hall.” Mr. Oishi said.

The idea of contracting the inspection business started from market needs.

Japan’s manufacturing has been building a structure which does not produce defective products in the production process. On the other hand the production fields other than Japan have been manufacturing products rationally, finding defective products before delivery and not allowing any problem to happen even though there is uneven quality or a quantity difference. Now it is an age of globalization for manufacturing, aiming at defect-free process completion, keeping competitive pricing power and maintaining quality as well. We understood that the accuracy of quality and quantity will affect production processes later, so the market is gradually getting to a point where every process requires high quality and does not accept any single defect, including quantity. That’s why the total inspection before delivery is required. The number can reach the millions or tens of millions depending on the parts.

The staff working to do an inspection ( We are not providing the contracting service of sorting work using sorting staffs.)

Capable of conducting sorting inspections for more than 100,000 parts a day.

The Taiwanese high-speed automatic sorting machine “VIZION”, which Nano Seimitsu has concluded an exclusive agency agreement for Thailand can sort 300-800 parts per minute automatically. Only the machine set up in the sorting house allows more than 100,000 parts a day to be inspected with only 8 hours of operation. If we extend operation hours and increase the number of machines in operation, we can respond to inspection demand greater than that.

On the turntable, a maximum of 4 cameras will capture various large and small objects and the three-dimensional inspection will proceed. There will be not even one defect and the quantity will be correct. The machine enables a higher-quality inspection than human sight can never do. Current demand is mainly for cold forged parts, but it can also inspect different materials like rubber and resin in addition to pressed products, castings and sintered metal.

”I am sure that this field will grow much larger in the future.” Mr. Oishi said. “Because of that, I wanted to create a demonstration hall having the function of a showroom like this,” he said.

High-speed automatic sorting machine “VIZION”

Provide high-level inspection to not cause an “incident”

”It will be a big problem if even only one defective part in 10 million parts was found out. In this world, this is a serious incident.” In the interview, Mr. Oishi repeated the word “incident”. “Something that shouldn’t happen” and “not to cause an incident”. I felt he has pride as a craftsman who has been developing Japan’s manufacturing.

Nano Seimitsu who found a new challenge and possibility in a changing market and is going to support Thai manufacturing for a new generation.