Date:

December 16, 20

'Automatic sorting in Thailand' of Nano Seimitsu Co., Ltd)! With key business partner NAIDE, a manufacturer of customizable automation and customizable automated assembly machines.

At present, the manufacturing industry around the world, including Thailand. They focus on the widespread adoption of automation and labor reduction policies. Due to the problem of labor shortage and the rising wages

Throughout the years Nano Seimitsu has been devoted to the development of calibration equipment such as high-speed automatic sorting machines in use in Thailand. Semi-automatic external analyzer Including automatic adjustment of the device used to measure dimensions, shapes, weights, objects outside the set limits.

The transition to automation is not something that can be clearly presented in a very concrete way. It is like the heart of the work that needs to be switched to automation, for this reason Nano Seimitsu has decided to partner with YUYAO NAIDE AUTOMATION TECHNOLOGY (aka NAIDE) from China. They are experts and have a lot of experience in this field. To expedite the introduction of automated operating systems in Thailand

Nano Seimitsu's customers are increasing according to the trend of automatic switching which is gaining popularity in Thailand.

Even FORTUNE CROSS, the head office of Nano Seimitsu, has also begun to switch to automation with some analysis processes. In other words, purchasing a 6-point automatic measuring device for use with axle products from NAIDE is part of the transition to automation.

▲ Fortune Cross Thailand 6 point automatic measuring device

Currently, there has been an increase in orders for automation equipment at Nano Seimitsu since 2019, so in this article, we will get to know some of the projects that Nano Seimitsu is involved with.

Automatically change some analysis processes to the system.

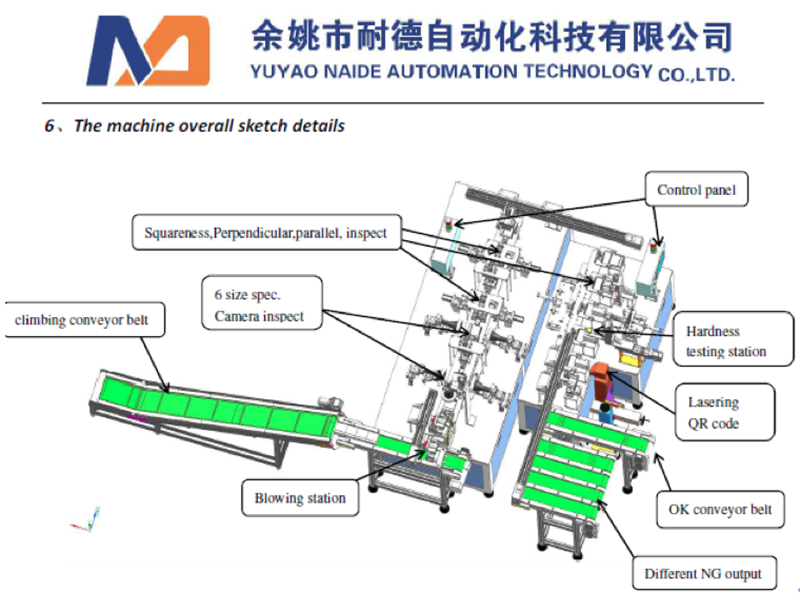

T Company is engaged in the business of aluminum hot forging and processing parts such as building materials. Auto parts in Thailand The company above wants to automate the process of aluminum square cut materials.

Company name : Company T (Bangkok, Thailand)

Job description: Push forming aluminum Manufacture and sale of processed parts

Process to switch to automatic :

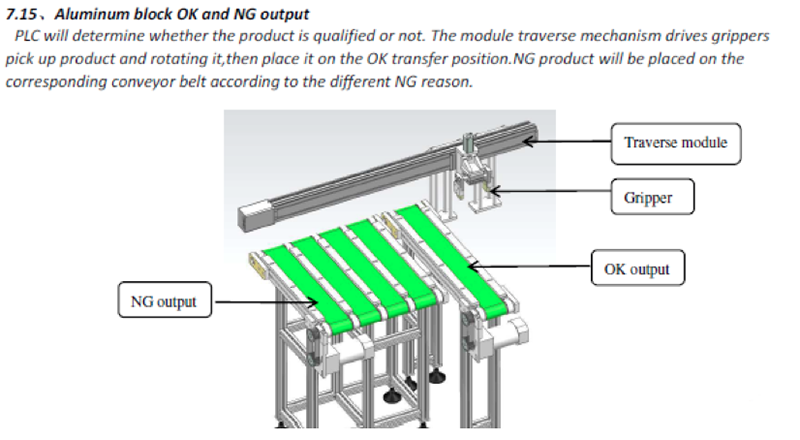

① Deburr or deburr after cutting

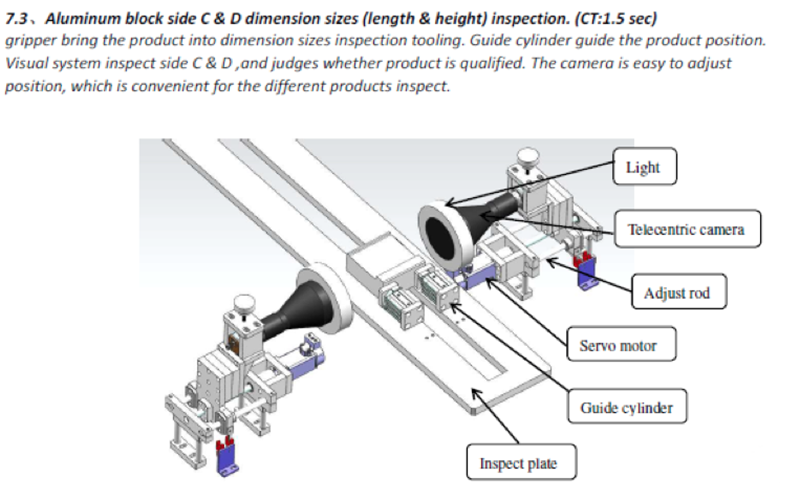

② Auto check size

③ Measure the hardness of the workpiece

④ Laser etched QR code

Our partner NAIDE not only sent a quote for this project, but also created Concept Books to summarize the LayOut and explain the structure. Mechanisms work at every step Exhaustive To make customers easy to understand as well This will give customers a clearer understanding of the job description and feel comfortable choosing to use our services.

Example of Concept Books from NAIDE Company

NAIDE's strengths include design ability, layout, And the ability to compete in the price to be unrivaled. Certain types of jobs may be half the price of the general Japanese group market. The said price will not be out of reach If you make a mistake by ordering main parts such as cameras, and head sensors from Japan or Western countries Then choose to use the machines or mechanisms that are available in the country as much as possible

Our company is ready to learn more and better approach the needs of our customers in Thailand. Including expanding the scope of service offerings "Change the production line in Thailand to automatically go into the system"

・Thinking about the transition to automation But there is no incentive to make decisions.

・I want to change the login automatically. But stuck in the cost problem

・Want to plan to reduce costs With the introduction of automation and reducing the number of workers

・Want to increase production quality

・Want to eliminate problems of faults and broken pieces Caused by personnel in the workplace

If you are considering any of these You can consult our company immediately. We are here to provide you with some useful tips to help you make your decision.