Date:

June 17, 24

Workpiece inspection machine Production technology that is important to achieve production goals and reduce lost work to zero In today's era, the manufacturing industry is developing rapidly. The demand for high-quality products has become impossible to ignore. Making tools that help in checking quality such as "Inspection machine and Sorting machine" is considered an important part that helps production to be efficient and accurate. Especially using high-speed cameras to detect workpieces with high production speeds. To make it easier to understand Let's get to know what a workpiece inspection machine is and what its functions are.

The workpiece inspection machine is

An inspection machine is an automatic machine designed to inspect and analyze the quality of workpieces in a production line. This inspection uses an auto-inspection machine that can capture images of the workpiece at high speed and in high resolution. To check whether the workpiece is produced to meet the quality standards or not. This reduces production errors and increases product reliability.

The function of the workpiece sorting inspection machine

inspection machine The main function of sorting workpieces is to check for abnormalities in the workpieces. From roundness, size, shape, scratches, bumps, and foreign objects in the workpiece. Using high-speed cameras to inspect Helps the inspection to be fast and accurate. These machine-based inspections allow for the reduction of manual inspections that can be subject to errors. It also helps reduce inspection time.

Why do shaft manufacturing plants need inspection machines?

A factory that produces shafts used in various industries. Need production with high precision and durability in order to deliver quality spare parts or parts to customers. Having a sorter is very important for the following main reasons:

Reduce costs, reduce people

The use of production inspection machines eliminates the need for labor in traditional quality inspections. This often requires a lot of labor. and there is a high chance of errors occurring The sorter can work quickly and continuously. It reduces the cost of errors and reduces the need for human labor in quality inspection.

Dispose of it before delivering it to the customer.

Using part sorters in the production process allows factories to detect and remove problem parts before they are sent out to customers. This helps prevent the delivery of poor-quality products and reduces the chance of losing customer confidence.

Precision in production

Shafts must be manufactured with high precision. Because it plays an important role in the transmission of power in many types of machines, having an Inspection machine allows for detailed inspection of the precision and quality of each workpiece. This results in accurate and reliable production.

Having an inspection machine in the shaft manufacturing plant not only helps ensure the production process is accurate and of high quality, but it also reduces costs and increases competitiveness in the industry.

The Workpiece inspection machine from Nano Semitsu is accurate, durable, and meets Japanese standards.

When it comes to reliable and highly efficient production technology, one name that is often mentioned is Nano Semitsu, a company that sells inspection equipment. Work sorting machine and production technology that is internationally accepted With technology and innovation from world-class brands There are various models of inspection machines to choose from as follows:

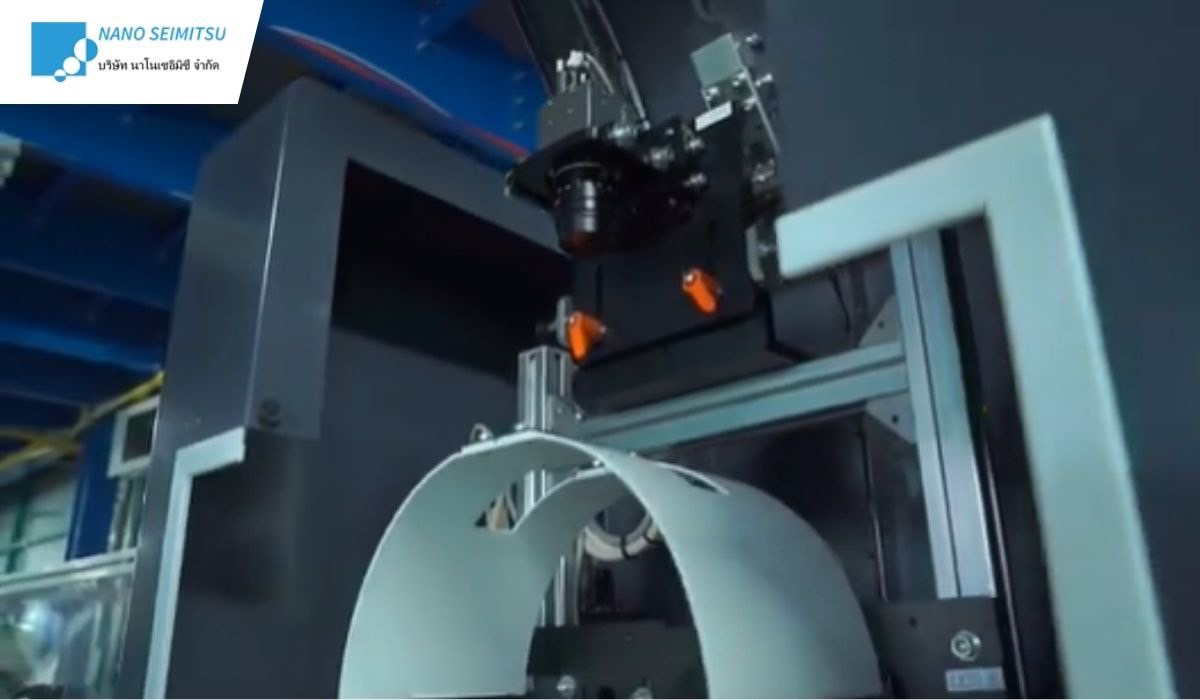

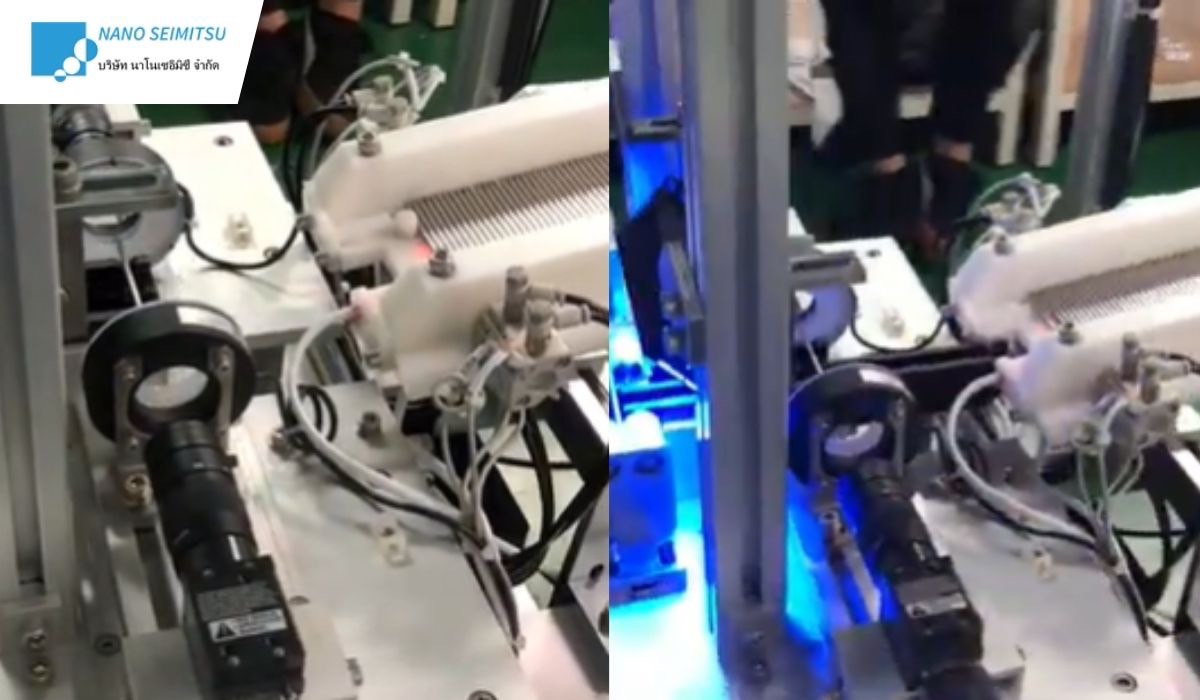

The SAC Series from Nano Semitsu is a semi-automatic inspection machine designed to meet the needs of applications that require high speed and precision in inspection. No audit training required for employees Simply feed the workpiece into the inspection machine and the workpiece can be inspected immediately. from the use of high-speed cameras for inspection Shaft length: up to 150mm Diameter: 3 to 10mm including cylindrical workpiece Height: 50mm Diameter: 10 to 30mm Workpieces can be inspected in 1 to 2 seconds per rod (including rotating and manipulating time work) can detect scratches, bumps, and foreign objects from 0.15mm and up.

The external inspection machine around and on both sides of the shaft manufactured by DECSYS uses the best image processing technology in the industry, making it possible to detect defects such as foreign objects, dirt, scratches, bumps, etc. even if Its size is only 0.2mm, allowing for quick and highly accurate inspection of the external condition of the workpiece. without having to rely on human inspection